Processing & Machines

We create advanced added values in films, and deliver products that satisfy customer requirements with superior processing technologies based on our improved production facilities.

Multilateral approaches that even cover raw materials and persistent trials are major characteristics of HYNT. We offer molded and processed films that perfectly satisfy customer requirements by combining our film processing specialists' secondary processing technologies for "bending," "laminating," "cutting," and "forming."

Different processing methods can be combined.

Multiple processing methods can be combined for optimal results depending on customer requirements.

HYNT's Consigned Processing Services

-

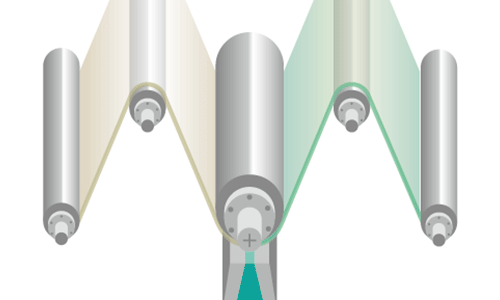

Coating

CoatingTo evenly coat a base film (base material) with organic solvent or dissolved resin. There are two application methods: "direct" and "gravure."

Learn more -

Lamination/Slitting/

Lamination/Slitting/

Inspection equipmentLamination is to laminate films in a roll-to-roll method. Slitting is to cut the film in TD (transverse direction) and MD (machine direction) in a roll-to-roll method.

Learn more -

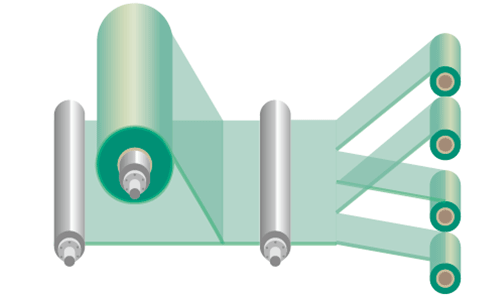

Sheet Cutting

Sheet CuttingTo cut the film roll into sheets. The roll is first cut into large sheets in MD (machine direction) and then trimmed in TD (transverse direction) into a specified size.

Learn more

Other Processing & Machines

-

Aging room

Aging roomAfter the coating process, aging process is performed in a constant temperature environment at 40-60℃ (in an automated storage and retrieval system) to promote maturation and curing of the coat layer.

Learn more -

AGV

AGVDuring storage, film rolls are hanged in the automated storage and retrieval system (AS/RS). AS/RS and the production line are connected by AGV (automatic guided vehicle) for transporting films without intervention of operators.

Learn more

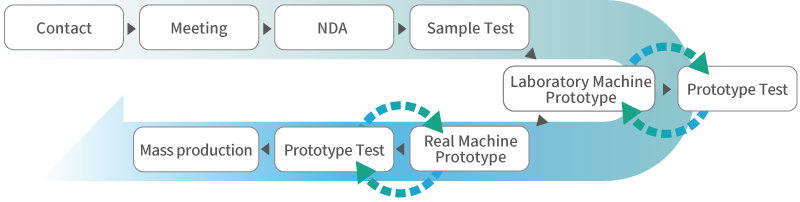

Manufacturing in cooperation with clients

HYNT assigns a dedicated engineer to each project who handles entire processes from prototyping to mass production. We formulate appropriate solutions based on our vast experiences and results and propose optimal equipment to solve problems that our clients face. Please feel free to ask any question or consult with us for your specific needs for processing. We ask clients to join the prototyping process as we do technical development and processing with focus on cooperation with clients.

*We offer clean suits and shoes for clients. Please inform us of sizes in advance.

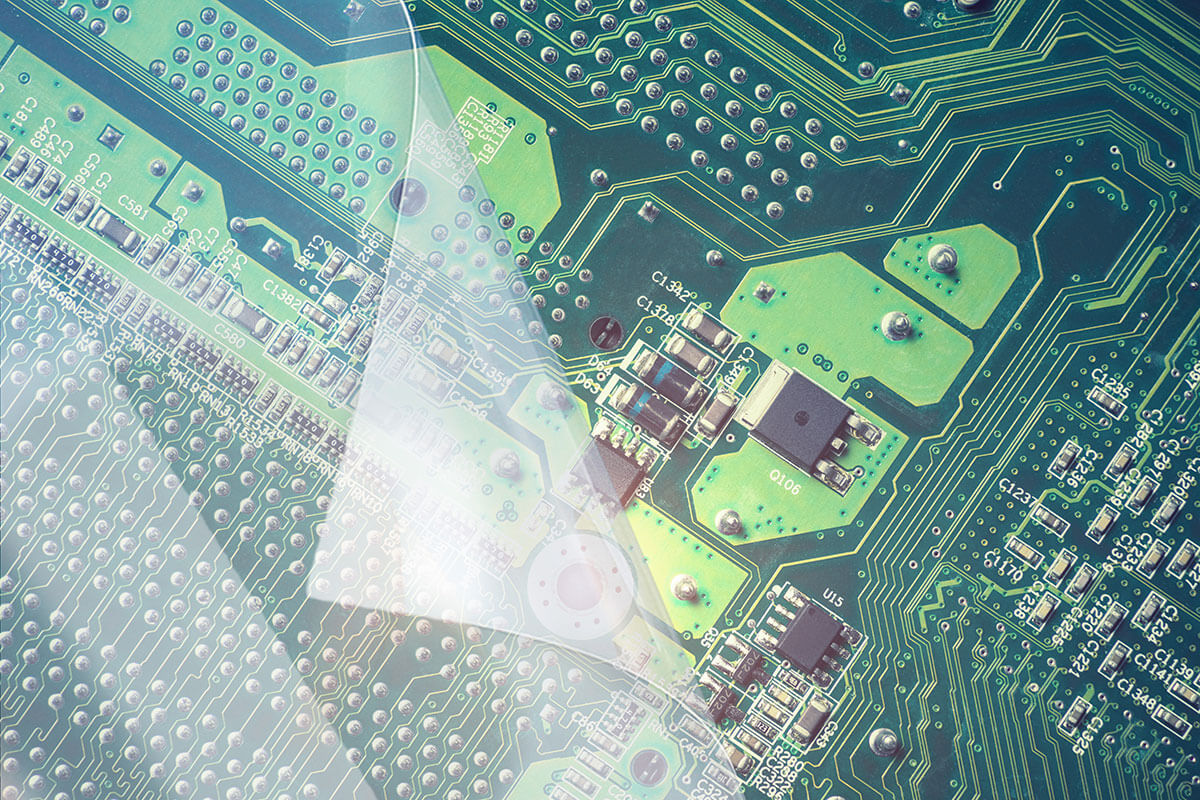

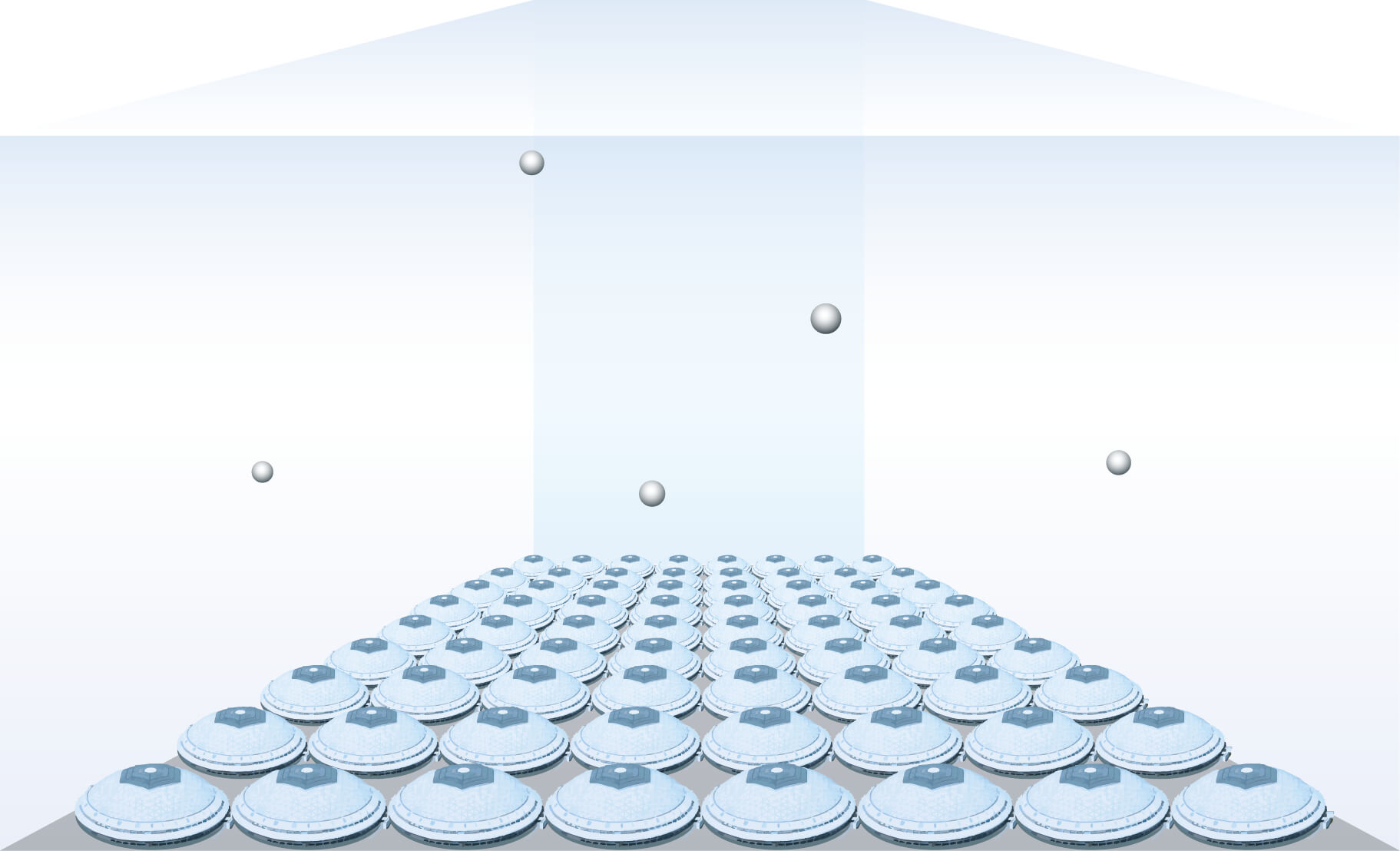

Class-100 Clean Room with Advanced Equipment

Cleanliness is measured by particle count larger than 0.5μm in diameter per cubic foot and Class 100 cleanliness means the particle count per cubic feet is 100 or less. Manufacturing in this cleanliness level effectively prevents defects and nonconformity caused by dust. Abilities to maintain and manage the advanced clean room are one of our strengths.

*1μm (micron) = 0.001mm, 1ft (foot) = about 300mm

Hair: 20-100μm

Pollen: 10-100μm

Cigarette smoke: 0.01-1μm

P.D.Lab.

We have a "Processing Development Laboratory" that enables us to respond promptly to diversifying film needs by developing films, cooperating with processing manufacturers, specializing in secondary processing technologies, and manufacturing, prototyping, testing, and evaluation of samples.