Coating

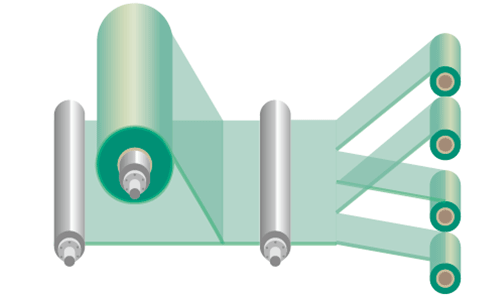

A film set on the feed roll is fed into the coating head where the film is coated with coating slip. The coating slip is dried in the dryer and then the film is rolled up into the winding roll.

We have coating heads for different coating methods compatible with various types of coating slip, and there are ultraviolet irradiation equipment and a corona treater, etc. in our manufacturing processes.

There are various other accessories and auxiliary facilities such as inspection equipment to defect detection equipment in the coating process and secondary winding equipment capable of laminating a protective film while winding, etc.

Specifications

| Base material thickness | 5-250μm |

|---|---|

| Maximum base material width | 1700mm |

| Maximum roll diameter | φ850 for feed roll / φ1000 for winding roll |

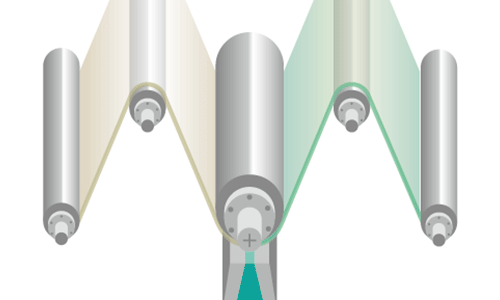

Coating Methods

- Direct coating

- Reverse coating

- Small-diameter gravure coating

- Slot-die coating

Accessories

- UV irradiator

- Corona treater

- In-line spectrophotometer

- Inspection equipment

- Laminator, etc.

Coating (Test coater)

This equipment allows for test coating in a quasi-production environment. For its compact profile, test coating can be performed with small amount of base film material and coating slit, etc. The roll-to-roll structure can wind the test-coated product to make a roll sample.

Specifications

| Base material thickness | 8-500μm |

|---|---|

| Maximum base material width | 500mm |

| Maximum roll diameter | φ400 for feed roll / φ400 for winding roll |

Coating Methods

- Direct coating

- Reverse coating

- Small-diameter gravure coating

- Slot-die coating

Accessories

- UV irradiator

- Laminator, etc.

Machines

Please feel free to contact us with any questions or inquiries regarding products and processing we deal with from this form.