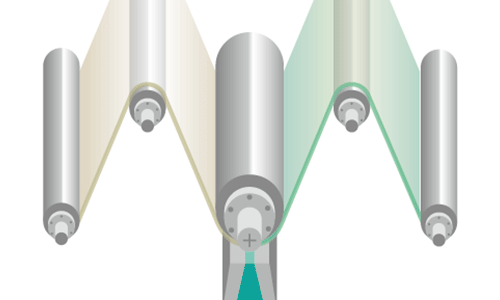

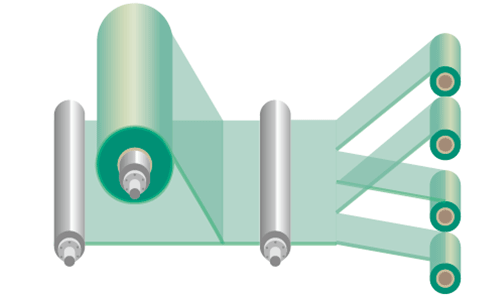

Lamination/Slitting/Inspection equipment

These machines allow for processing such as laminating a different base material over a film fed from the feed roll, and cutting a film in TD and MD before winding. Some machines can work in a clean environment. We offer lamination and slitting services not only for our own products but also for carry-in products supplied by clients.

Lamination and slitting can be done at the same time. Some machines are equipped with inspection equipment that detects any defect and foreign substances, etc. We can handle various processing scenarios such as lamination and slitting at the same time with film defect inspection.

Specifications

| Base material thickness | 12-300μm |

|---|---|

| Base material width | 250-1800mm |

| Maximum roll diameter | φ900 for feed roll / φ900 for winding roll |

Inspection equipment

Specifications

| Base material thickness | 25-250μm |

|---|---|

| Base material width | 400-1400㎜ |

| Maximum roll diameter | φ800 for feed roll φ800 for winding roll |

| Inspection equipment | Inspection by reflection and by transmission can be done at the same time |

Specifications

| Base material thickness | 16-250μm |

|---|---|

| Base material width | 500-1800㎜ |

| Maximum roll diameter | φ900 for feed roll φ900 for winding roll |

| Inspection equipment | Inspection by reflection and by transmission can be done at the same time |

Machines

Please feel free to contact us with any questions or inquiries regarding products and processing we deal with from this form.