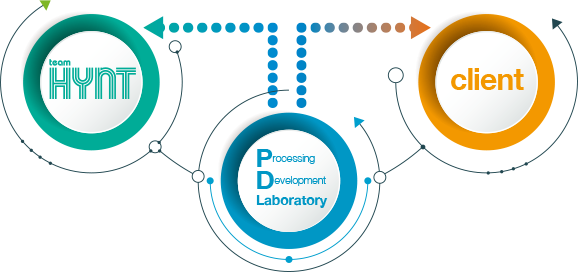

Processing Development Laboratory

Processing Development Laboratory

"Monozukuri" begins from here

We have a "Processing Development Laboratory" that enables us to respond promptly to diversifying film needs by developing films, cooperating with processing manufacturers, specializing in secondary processing technologies, and manufacturing, prototyping, testing, and evaluation of samples.

By accelerating development speed, advanced wet coating technology, and clean management, we will achieve to develop and produce a wide range of film products in-house that meet customer needs, such as hard coat films, release films, adhesive, and protective films.

Shaping ideas!

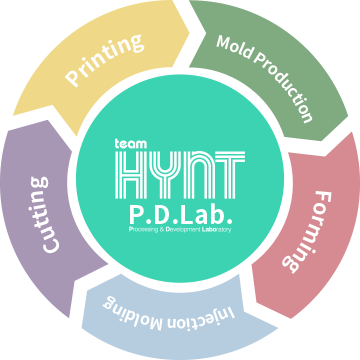

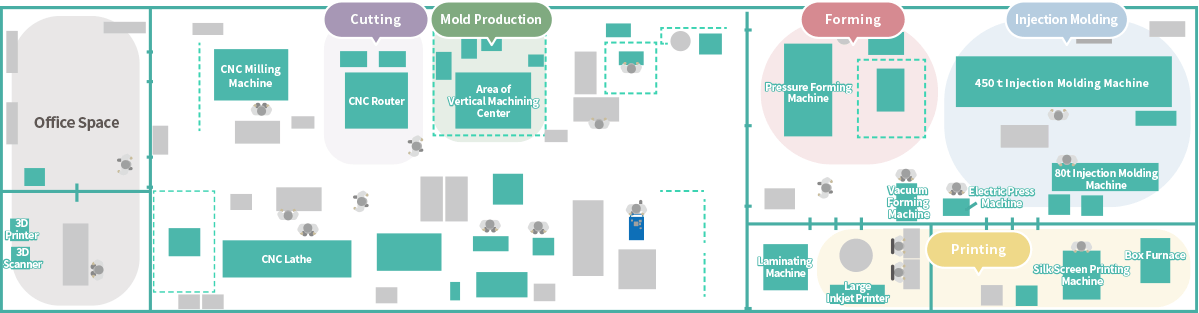

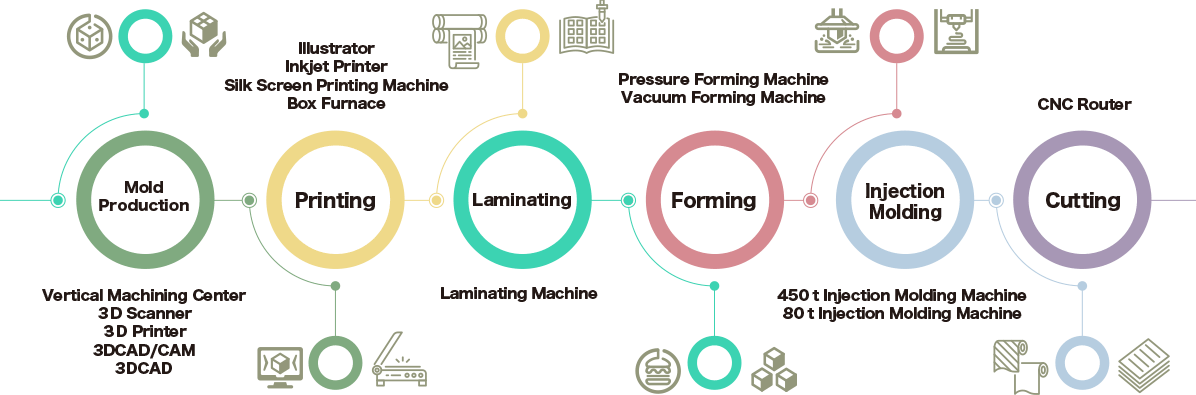

Manufacturing of metal-dies, completion of prototype models and sample products, various tests, measurements and evaluations, verification of processing methods, etc., we are responding to a variety of projects by making full use of a wide variety of equipments.

From film processing to insert molding, all the process in one facility

From prototype verification tests and evaluations to coating liquid development, analysing trial production and joint development.

We, Higashiyama Film, are feasible to provide an integrated process to support our customers in solving their problems, realizing their ideas, and conducting research and development.

Facilities Introduction

Mold Production

Vertical Machining Center

This machine can automatically switch tools such as drills and end mills on the rotating spindle and performs 3D-shaped objects by cutting the workpiece. Total of 25 tools are built-in to be switched by ATC (tool automatic switching device) and can perform the accurate cutting by computer numerical control.

| Maximum machining size | 850㎜×550㎜ |

|---|

CNC Lathe (Computer Numerical Control Lathe)

A machine attaches a workpiece to a rotating spindle and performs turning such as outer diameter machining, inner diameter machining, and hole machining using a tool or drill. The accurate processing can be performed with a high precision by a computer numerical control.

| Swing on bed | 530㎜ |

|---|---|

| Swing on the round-trip table | 300㎜ |

| Distance between centers | 3000㎜ |

CNC Milling Machine ( Computer Numerical Control Milling Machine)

A device that attaches tools such as drills and end mills to the rotating spindle and performs cutting, such as plane machining, grooving, and hole machining on the workpiece. The accurate processing is possible by computer numerical control.

| Axial movement | X-axis 700mm, Y-axis 300mm, Z-axis 400mm |

|---|

3D Printer

| Molding size | 297㎜×210㎜×200㎜ |

|---|

3D Scanner

| Measuring range | φ300㎜×H200㎜ |

|---|

Printing

Silk Screen Printing Machine

A squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

| Maximum printing area | 550㎜(stroke)×750㎜(width) |

|---|

Large Inkjet Printer

| Maximum printing width | 730mm |

|---|

Box Furnace

| Max heating temperature | 90℃ |

|---|

Forming

Pressure Forming Machine

This Machine makes the 3D formed film, workpiece is softened by heating and pressed to the die by high-pressure air.

| Maximum workpiece dimensions | 650㎜×550㎜(catalog) |

|---|

Vacuum Forming Machine(Made In-house)

This Machine makes 3D formed film, thermoplastic film is clamped against the clamper and then heated. The heated and softened film is sealed at the clamper, air in the closed space is suctioned by a pump and by pressure the film is forced to take the contours of the mold.

| Forming surface | 120㎜×210㎜~210㎜×297㎜ |

|---|

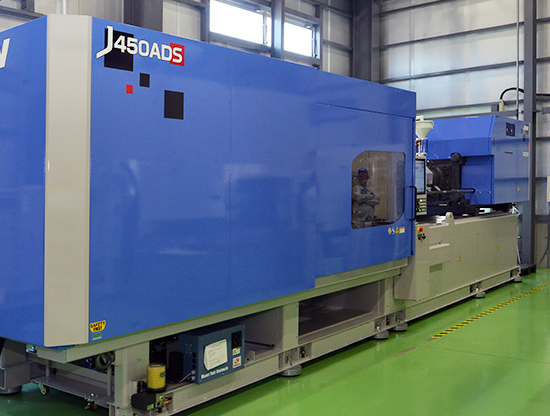

Injection Molding

450t Injection Molding Machine

This machine injects melted resin into a mold, cooling it, solidifying it to obtain a molded product.

| Clamping force | 450t |

|---|---|

| Die holding | Magnet clamp |

80t Injection Molding Machine

This machine injects melted resin into a mold, cooling it, solidifying it to obtain a molded product.

| Clamping force | 80t |

|---|

Laminating

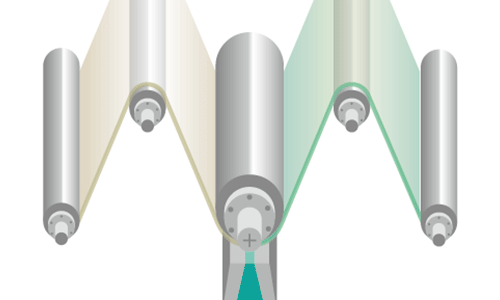

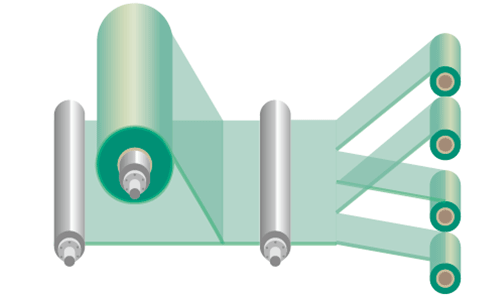

Laminating Machine (Made In-house)

This is a machine is used to bond the base film / sheet / plate to functional film.

| Maximum laminating size | 600㎜×600㎜ |

|---|

Triming

Electric Press Machine

This machine operates the shaft with a servo motor and pushes through the film shaped with a blade called Thomson type.

| Maximum load | 3t |

|---|

Cutting

CNC Router (Computer Numerical Control Router)

This machine is used for cutting, with tools such as drills (up and down directions), end mills (X, Y, Z-axis direction) and can perform the accurate cutting by computer numerical control.

| Table dimensions | 1200㎜×600㎜ |

|---|

Watch a video clip

We will introduce the equipment of the processing development building in an easy-to-understand video.

※Please refrain from reproduction and distribution of videos and images included in this video.

For those who wish to visit the Processing Development Laboratory, please feel free to send us a message by filling out the contacting format.

Machines

Please feel free to contact us with any questions or inquiries regarding products and processing we deal with from this form.